private label Seal Strength Tester|seal testing near me : Brand The Seal Strength Tester is an instrument designed to test : Seal Strength of Heat Seal Joints of Pouches. Can also be used with restricted functionality to test : Lamination Peel Strength. .

29 de abr. de 2023 · From the collapsible menu on the left, select All campaigns > Keywords > Search terms. Select Download and then select the Format and Segment .

{plog:ftitle_list}

Resultado da El Patrón Video Original Portal Zacarias Gore. En un rincón enigmático del vasto ciberespacio, surgió una joya digital que dejó una huella imborrable .

seal testing near me

Measure seal strength and package integrity with the Dansensor ® Lippke ® 5000. Perform burst, leak, creep, creep to fail and bubble tests from one instrument – or try the combined test option to conduct a simultaneous leak, .Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding and providing an indicator of package integrity throughout the life of the package for a variety of pouch package systems holding drug product or .This test is applicable to peelable medical package seals and a variety of heat-sealed packages. It can determine the force required by the end-user to open a peelable package as well as provide force data that can be used in validation .This Greener Tech Bite explains the objectives, methods, results, and limitations of seven common seal tests for packages produced by flow wrappers and vertical baggers. We begin .

Seal strength testing evaluates the mechanical strength of the seal, assuring proper bonding to maintain package integrity throughout the life of the package. Here we address two basic .The Seal Strength Tester is an instrument designed to test : Seal Strength of Heat Seal Joints of Pouches. Can also be used with restricted functionality to test : Lamination Peel Strength. .Seal strength is a useful measure to help predict the final integrity of a package. It ensures the package can provide and maintain a barrier for the product for sterility, freshness and overall .

C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & . Seal strength testing allows packaging engineers to design packages with desired seal strength, to verify seal strength specifications at different life cycle stages (in production, after sterilization, after transportation, .Benefits of Peel/Seal/Bond and Adhesion Strength Tester. The Presto Adhesion Strength Tester serves the purpose of measuring the enduring adhesion or peelability of self-adhesive pressure-sensitive materials. Peel .Accuracy and versatility in testing is vital, and the SST-3XS Seal Strength, Tensile and Compression tester provides the technology and range of options to deliver for your specific needs. An intelligent controller and touch screen user .

LSSD-01 Leak and Seal Strength Tester is designed for the quantitative measurement of leak, heat seal strength, heat seal quality and burst pressure of each heat seal edge of flexible packages that are made by heat seal and adhesive processing.CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cupsC660M Leak and Seal Strength Tester. C660M Leak and Seal Strength Tester can used for leak test, burst test and creep test of finished packages and three-side sealed packages, based on ISO 11067, ASTM F1140 & ASTM F2054.

Seal-strength testing can play a critical role when working to properly validate a package's design and document its conformance to specifications. This is especially true when dealing with a product in a sealed pouch or a package system that incorporates a tray configuration with a sealed layer closure system.Seal Strength Tester S10 Series. The Seal Strength Tester is an instrument designed to test : Seal Strength of Heat Seal Joints of Pouches; Can also be used with restricted functionality to test : Lamination Peel Strength; Tensile Strength (Breaking Load) Elongation @ Breaking Load; Technical Specifications of Seal Strength Tester:

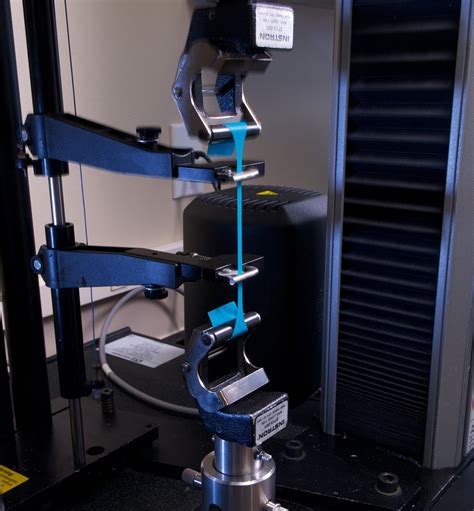

Peel testing is critical for evaluating the seal strength of various adhesive bonds. Some bonds, such as those that seal consumer packaging, are intended to be break at low forces, while others, such as those used in automotive applications, must withstand extreme conditions. . ASTM F88 - Seal Strength of Flexible Barrier Material ISO 29862 .

The peel/ seal strength tester is a very crucial lab testing instrument designed to help manufacturers from the flexible paper & packaging industry determine the peel ability of tapes, adhesive material, etc. to withstand peel strength. Achieving a certain level of peel strength provides a sense of assurance and safety in the minds of .

Before you can determine the best seal testing method for your flexible packaging application, you need to clearly identify your requirements for seal strength and hermiticity. Then you can use these criteria to evaluate different methods and to accurately interpret test results. . We begin with seal strength tests, followed by tests for .

Ramp Impex Private Limited. Karol Bagh, New Delhi No. 18, Ground Floor, Karol Bagh, New Delhi - 110005, Dist. New Delhi, Delhi . Pet bottle seal strength tester; ASTM D903 Peel Strength Testing of Adhesive Bonds; Have a Question? Ask our expert. Speak your question. Please enter your question.demonstrate that the seal is intact. • Seal strength test. The Standard Test Method for Seal Strength of Flexible Barrier Materials (ASTM F88 / F88M - 15) is used to assess seal strength. However, in certain situations, testing seal strength using this method is problem - atic. This is because only one-inch sections of the seal are examined .This instrument can easily calculate the force required to tear the label or flexible films strip. The instrument provides the user with a computerized report facility. . Seal strength test 4. Bond strength test The instrument complies with various tester standards such as Standards – ASTM D429 – 14, ASTM D903CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

the life of the package. The Seal Strength also provides assurance of control of the “peelable” characteristic of the package. ISO-11607 refers to two methods which may be used to determine seal strength, tensile strength testing and burst or creep pressure (inflation) testing. Tensile Seal Strength Testing (ASTM F88) uses a defined

seal peel testing

packaging, gas flushed packaging, or packaging requiring a hermetic seal for the shelf life of the product. 6. Seal Strength test: The maximum force required to pull apart a 1-inch sealed package section is measured. Test results are often affected by the mechanical properties of the packaging material. Claire SandPresto group offers an advanced model of Hot Tack Tester which is used for testing the heat seal performance of films. [email protected] +91-9210 903 903; Get A Quote . Testing Hot Tack Strength of Flexible Packaging Films. . Presto Stantest Private Limited. I-42A, DLF Industrial Area, Phase-1, Delhi Mathura Road, Faridabad-121003 .

Seal Peel Test. The Seal Peel test determines the strength required to peel apart the seals for porous and nonporous packaging. This test meets the requirements for regulatory agencies to demonstrate the strength of a package seal. This test is performed in accordance with ASTM F88 “Standard Method for Seal Strength of Flexible Barrier .Seal Strength Testing For Product Packaging - MycoScience . MycoScienceSST-3XS Seal / Tensile Tester The SST-3XS Seal / Tensile Tester has been developed as a highly specialized machine to measure accurate low loads in tension and compression up to 50Kg (500N). The machine is ideal for seal strength measuring and general tension and compressive testing as re-quired by the packaging, plastics and paper industries.HST180 Tall Seal Strength Tester for Larger Trays and Pouches (sample width 1/2″, 1″, 15 mm, tray max 5.0″ deep) CPT200 Seal Strength Tester for Compact Packages (180° pull, 2″ max lid diameter) MCD100 Seal Strength Tester for Flexible Packages (sample width 1/2″, 1″, 15 mm) 1; 2;

Are you tired of dealing with labels and laminates that just won't stick? If so, it's time to pay attention to its adhesion strength. Thus, we at Testronix Lab Testing Instruments have designed a high-quality lab testing instrument known as a peel adhesion bond seal strength tester computerized. This quality lab testing equipment ensures that your product labels and . Dye penetration test: An operator applies a dye to one side of the seal area and then examines the other side of the seal to assess if the dye transferred through the seal. Detectable leaks are six orders of magnitude larger than most permeants such as oxygen, carbon dioxide, nitrogen, so this method is not useful to detect small leaks relevant to modified .The Cobham Test-A-Pack Model F100-2600-3 Seal Strength Tester is the heart of the world’s most advanced package testing system. It automatically regulates air pressure to determine the seal strength of a wide variety of porous and non-porous packages used in the medical, food and pharmaceutical industries. The tester is ideal for performing

Seal-strength testing (ASTM F88) uses a defined-width sample of a package perimeter seal. A moving jaw pulls the sample apart at a constant speed while measuring the resistance force during seal separation. The test is particularly suited to peelable packages. A significant advantage to this test is its sensitivity, and a disadvantage is that .Presto’s Peel Adhesion/Bond/Seal tester is used to calculate the permanence of the adhesion ability of self adhesive force sensitive products.The adhesion strength of a product is defined as the pressure required for separating a coated substance, which has been applied to normal test plate under specified circumstances, from another plate placed at a specified angle with .CO2 transmission rate test by weighing method: Water vapor transmission rate test by inverted cup method: Non-destructive test for packaging seal performance: Multi-station packaging pressure test: Tensile test of packaging materials with ultra-long elongation: Heat-seal strength test for cap films of medical bottles, yogurt cups and jelly cups

star wars weapon drop test

WEB3 de set. de 2010 · After a painful and numb period in a gruesome swamp, he is rescued and brought to "Nosso Lar" (meaning "Our Home"), a .

private label Seal Strength Tester|seal testing near me